A Step-by-Step Guide to Setting Up Metal Barricades

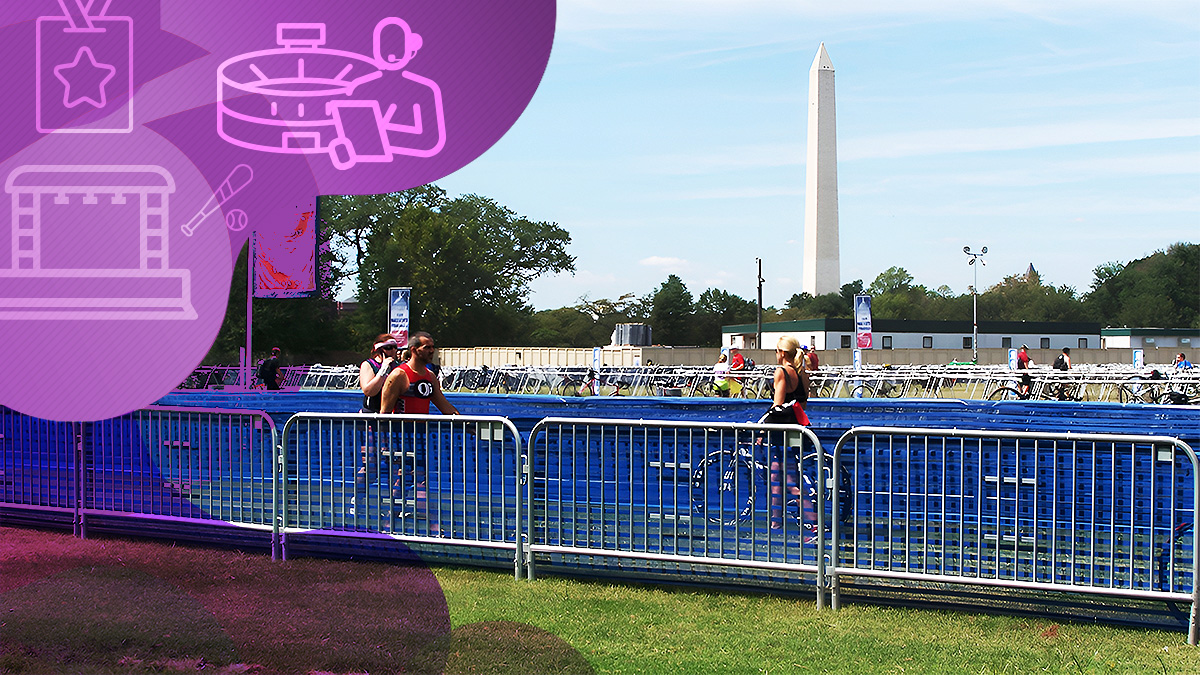

Planning an event? Learn how to set up metal barricades efficiently for crowd control and safety.

If you're thinking, "How hard can it be to set up a metal barricade?" You're right. It's not that difficult -- IF you are prepared. That means having compatible barricades with the appropriate feet to create stable barriers with corners. It means having enough interlocking barricades for the space with gates for easy access.

If you're looking at a pile of 7-foot barriers for an L-shaped walkway, it may take longer than the 30 minutes you have to finish setting up. That L-shape may lack stability if you don't have bridge feet. Without interlocking barriers, the 50 feet along a parade route may collapse with a crowd surge.

Being prepared is the first step in setting up metal barricades, beginning with selecting the appropriate barricades and accessories.

Step 1. Know Your Barricades

Metal barricades may be powder-coated with a layer of pigment for customized colors that last longer than standard paint. Using powder-coated steel barriers adds visibility without compromising weather-resistant capabilities.

Hot-dipped galvanized barricades can withstand harsh weather conditions without rusting. After assembly, the metal barricades are immersed in hot zinc for a weather-resistant coating.

Lightweight barriers may be sufficient for creating queues at outdoor events. However, heavy-duty barricades are more appropriate for crowd control, where people may press against the barrier.

When selecting barricades, it’s essential to consider their weight as a key indicator of quality and durability. Cheaper options on the market may have significantly reduced weight, sacrificing stability and long-term performance. These lighter barricades often use less steel, making them more prone to collapse under pressure. Choosing heavier, well-built barricades ensures you won’t need to replace them frequently, offering better return on investment, especially for rental purposes.

Metal barricade length

Heavy-duty steel barricades come in different lengths, ranging from 6.5 to 8 feet. Most lightweight barriers come in 6.5 and 7.5 feet lengths. While having a standard length for all barriers makes storing and transporting more manageable, it does not provide configuration flexibility.

What happens when you need a barricade line 80 feet long and only have 7-foot barriers? How do you compensate for the missing three feet? Customers will be unhappy if they must place personnel in the space to keep people out.

Interlocking Barricades

Interlocking barriers provide added stability for crowd control. Without interlocking capabilities, individual steel barriers can be easily compromised, allowing people into restricted areas.

When purchasing new barricades, always opt for interlocking models. These models feature loops on one side and hooks on the other. The top hook must have a bent end; without this feature, crowds could potentially lift the barricade and unlock it.

The bent hook ensures a safer perimeter by preventing easy disassembly. To interlock the barricades, insert the hooks at an angle into the loops of the adjacent barricades, creating a solid and continuous barrier line.

Barricade Compatibility

Metal barricades are designed to last. So, what happens when you need to purchase more panels to accommodate a growing business? Can you purchase new barricades that will be compatible with your existing ones?

To determine compatibility:

- Measure the distance between the interlocking loops on an existing panel.

- Measure the distance between the upper and lower hooks on the other side of the barricade.

- Measure the distance between the lower hook and the ground.

Finally, compare the measurements with those of your planned purchase to determine compatibility.

Step 2. Select Multiple Feet Types

Pedestrian barricades usually come with one of three types of feet. That doesn't mean you must use the same feet for every installation. Most barricades have interchangeable feet, meaning you can replace flat feet with roller feet when needed.

The following options are available:

- Flat feet are used on surfaces such as sidewalks or parking lots where surfaces are reasonably uniform. The feet are designed to sit flush with a flat surface to minimize trips or falls. Most flat feet will grip concrete for a more secure installation.

- Bridge feet are designed to stabilize barricades on uneven ground. They work like bridges by raising the barrier to rest above the surface. Level surfaces are difficult to find in outdoor venues, making bridge feet a necessity.

- Roller feet provide portability in environments where it might be necessary to reconfigure barriers quickly. Outdoor concerts or other venues may use roller-feet barricades to accommodate changes during day-long events.

A supply of all types of feet ensures you have what you need, regardless of the venue or location.

Step 3. Consider Accessories

Custom barricade covers are an excellent marketing tool for you or your customers. Depending on where you place the barricades, a custom cover can act as a low-cost billboard.

Place the covered barricades in specific locations for maximum visibility. Since cover sizes may not fit all lengths, check the cover measurements or look for universal covers that fit most barricades.

Another accessory to consider is a portable storage cart. Although not essential for setting up metal barricades, they make transporting barriers to and from venues less cumbersome. Consider the time required to move the barriers from the unloading location to the setup location when calculating setup time.

Step 4. Configuring Metal Barricades

Before arriving onsite, you should know the barricade requirements. For example, how much space is available? Will the barriers be in a straight line? Will security workers need to move through the line of barriers? Answers to these questions will determine whether corners and gates will be required.

For example, a street barricade should keep people safely out of the event space but provide exits facing away from the event for those who want to leave the event early. Queues may require corners if long lines are expected in a small space.

If people cannot see where the line begins, they will step out of a queue or push forward to see where they are in line. Weaving steel barricades allows individuals to determine their position but requires corners to work.

Setting Up Corners

Corners require a small bridge for the bottom barrier and a larger or taller bridge for the top. Set the barrier panel with the larger bridge at a 90-degree angle to the panel with the smaller bridge.

The smaller bridge should securely slide under the taller one. Interlocking the edges creates a strong barrier.

Using Swing Gates

Interlocking steel barricades increase stability; however, removing a barrier to allow vehicles or personnel through disrupts the barricade's integrity. Gates enable people to move from one side of the barricade to the other without compromising the barrier's integrity.

Standard swing gates allow pedestrians, officials, and staff to move through metal barricades. Wider swing gates accommodate wheelchairs and equipment dollies. Wide gates enabling emergency vehicles to pass through may be needed in locations where alternative access is unavailable.

Knowing Your Constraints

Making a diagram of your installation reduces the time needed to set up barricades and minimizes errors. It also allows you to operate multiple crews because you do not need to be present to execute each plan.

- Determine the available space. For example, parade barriers would cover the parade length plus any holding areas for participants at the start and end of the parade.

- Determine access requirements for officials, performers, staff, security, and emergency personnel. What size swing gates are needed? Will security need space to patrol the perimeter? Make sure to have enough clearance to accommodate opening and closing gates.

- Determine if marketing covers will be used. Customers may have specific locations for their marketing displays. These requirements must be considered when creating the barricade layout.

Knowing site constraints ensures that a plan will meet site requirements.

Designing Your Layout

Begin your layout by determining where the first panel will rest, then measure to the end of the line or the first corner. Divide the distance by the length of your panels, adjusting the panel lengths as needed.

For example, ten 8-foot panels are perfect for an 80-foot barricade. However, eleven 6.5-foot panels plus an 8-foot panel would cover 79.5 feet, which may be sufficient, depending on the venue.

Crowd management barricades

Venue safety is the primary concern when setting up metal barricades, their goal is to help maintain order so that event attendees can engage in an enjoyable experience.

These barriers are designed to control the flow of crowds, prevent unauthorized access, and create clear pathways for both attendees and emergency responders. By strategically placing barricades, organizers can guide the movement of people, minimize bottlenecks, and reduce the risk of accidents or injuries.

Additionally, using barriers with clear signage and ensuring that they are easily visible helps direct and inform the crowd, enhancing overall safety and organization.

By combining crowd management tools such as barricades with effective crowd control tactics, you can ensure a successful and safe event. Keep reading to learn more about crowd safety here!

Trend now

Fence Privacy Screen: The Missed Revenue for Rental Companies

Grow profits by over 100% with fence privacy screens. See the numbers, customer benefits, and how SONCO makes it simple.

Greener Shows, Greater Impact: Sustainability in the Live Music Industry

In a competitive market where experience and perception impacts attendance, sustainability is a business advantage as well as a moral responsibility.

Parking Lot Safety Tips for Venues and Arenas

A safe and efficient parking lot sets the tone for the entire event experience, starting from the moment guests arrive.